The idea

The company Growe from Barßel is a leading producer of roller shutters and sun protection systems. As a manufacturing company the optimization of production processes is always of interest. The technical management decided to break new ground: Up-to-date hall layouts were to be drawn up containing all machines, storage positions and other inventory. These then reflect the current situation and serve as a data basis for a potential production optimization. The production of the roller shutter and sun protection systems is located in four halls on a total area of around 4,000m².

The execution

A measurement accuracy of a few centimetres is sufficient for preparing the installation plans. Therefore, the choice of the measuring device to be used is quickly made on the mobile laser scanner "ZEB Revo RT" from GeoSLAM. This mapping system enables an efficient and at the same time precise data capture.

The measurement was carried out after the end of production to avoid ghosting effects in the scan data. In total, it took a little more than one hour to capture the four production halls (4.000m²) – a real time advantage compared to other scanning systems.

One scan was started per production hall. Since three of the halls are connected to each other via passages, care was taken to ensure sufficient overlap at these points so that the various scans could be connected to generate a large point cloud afterwards. During the scan, a video stream was taken via the camera integrated in the ZEB-Revo RT. The video helps the modellers to orientate themselves in the point cloud and to classify the entire inventory.

The preparations for the plan creation

The analysis of the data was done with the help of the software solutions GeoSLAM HUB and GeoSLAM DRAW/PointCab.

The processing of the individual scans is made up of the following steps:

- Downloading the scan data from the ZEB-Revo RT via the WLAN interface

- Unpacking and post-processing of the individual scans (with GeoSLAM HUB)

- "Merging" (i.e. combining) individual overlapping scans into one large overall scan (with GeoSLAM HUB)

- Creating a Geoslam Draw or PointCab project, in order to be able to generate simple sections and floor plans later during the plan creation (with GeoSLAM HUB)

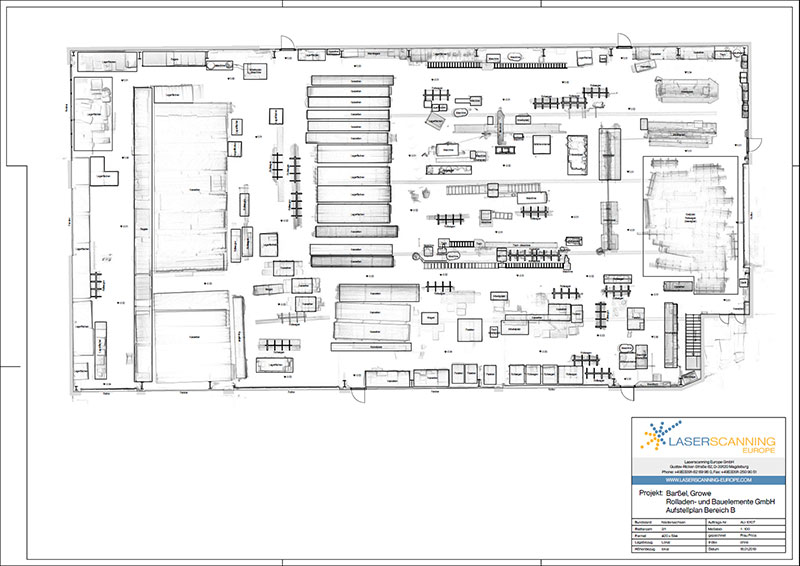

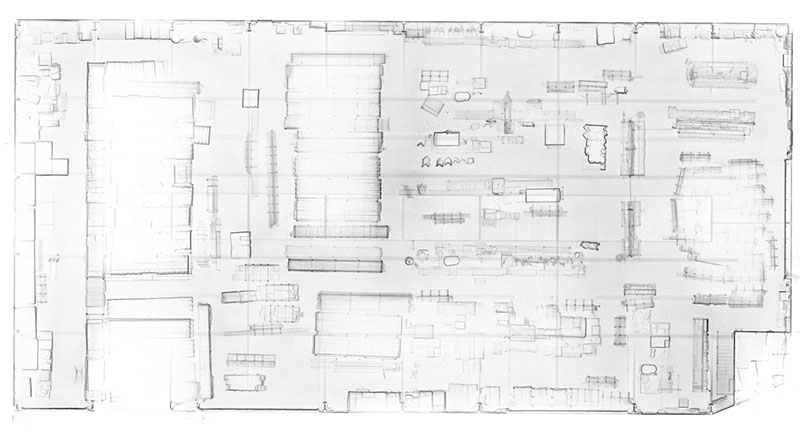

Point cloud of hall 1 created with GeoSLAM ZEB-Revo RT

Point cloud of hall 1 created with GeoSLAM ZEB-Revo RT

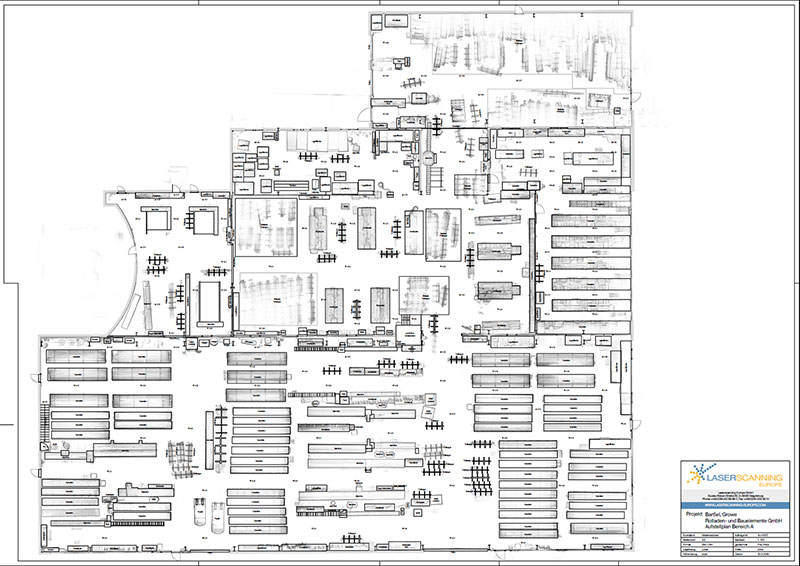

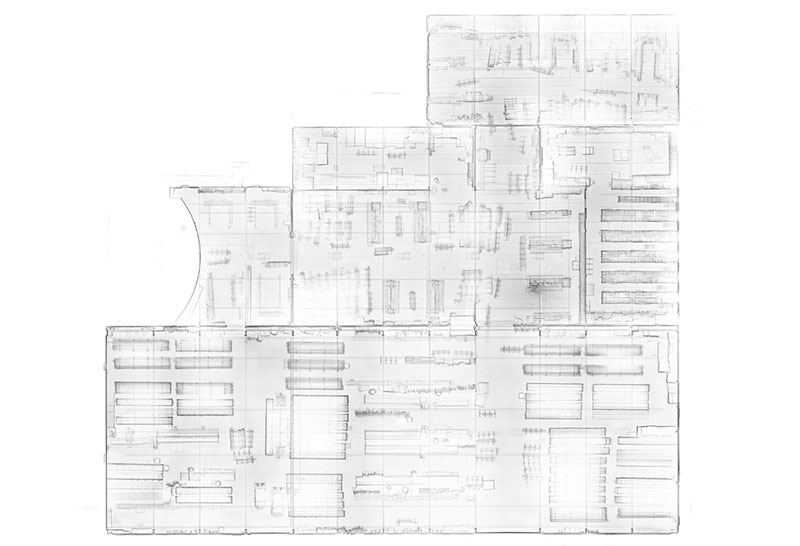

Point cloud of hall 2 – 3 created with GeoSLAM ZEB-Revo RT

Point cloud of hall 2 – 3 created with GeoSLAM ZEB-Revo RT

The plan creation

The results

The results have exceeded the expectations of the customer. A decisive advantage over manual measurement is the speed at which the production halls could be captured. Production did not have to be interrupted, as the pause times in the individual production areas were sufficient for the measurement. The fact that the GeoSLAM scanner generates much smaller amounts of data compared to a terrestrial laser scanner also accelerates the analysis process enormously, so that the drawing of the plans could be started immediately after the measurement.

The final plans now serve a specialist for production optimization as a basis for an improved installation of the installations and workbenches.