Survey environment

The survey environment are manholes that serve as access for maintenance and cleaning of the sewer system. The manholes usually have a diameter between 600mm and 800mm and are constructed with iron or brick steps to facilitate access and egress for people.

Problems related to the surveying of manholes

In order to document the condition of the shafts, an inspection of the shaft system is required. This can be done by specially trained operators by means of visual inspection. However, this requires a person to enter the shaft. The person has to be protected by additional personnel and safety equipment (CO2 measuring device, tripod with rappelling technique, climbing harness, special work clothes, etc.) in order to avoid personal injury.

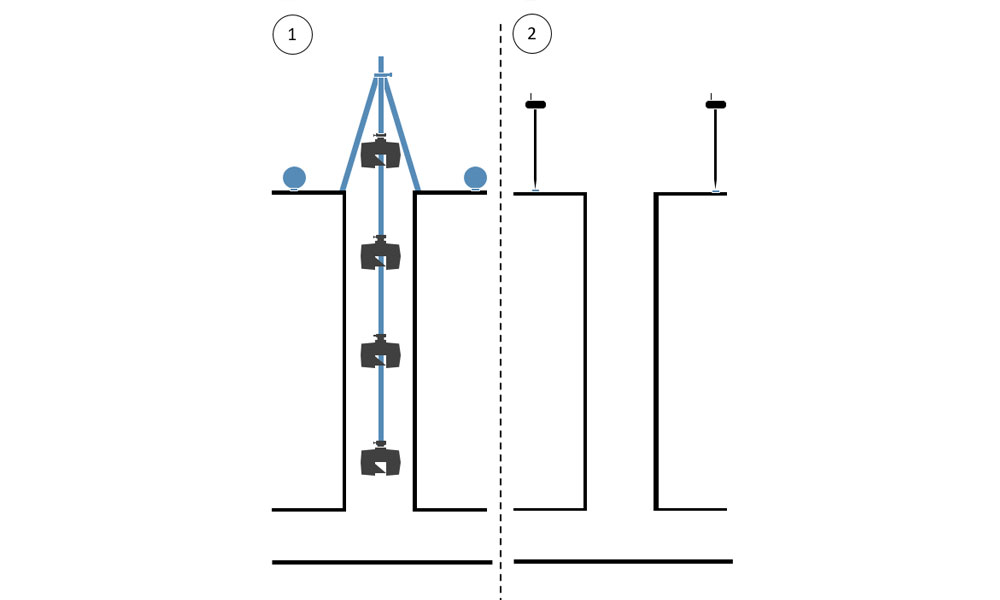

One approach to avoid personal entry into the shafts is to scan with a laser scanner. By using a manhole tripod (2-way tripod), the laser scanner can be lowered into the shaft. Reference spheres (spherical targets) positioned close to the shaft are also detected by the laser scanner and subsequently surveyed tachymetrically or by means of GNSS survey to ensure georeferencing.

Equipment for manhole surveying

The following equipment was used for the survey of the shafts:

- Laser scanner from the manufacturer FARO (other equipment is also possible).

- 2-way telescope tripod / manhole tripod from Laserscanning Europe (The manhole tripod is available with safety adapters for various scanner models).

- Overhead adapter for FARO laser scanner from Laserscanning Europe

- At least 3 reference spheres (type FLEXI) from Laserscanning Europe

- GNSS receiver (or total station equipment) for georeferencing

- If necessary, barrier type or similar to secure the shaft opening

Procedure of the survey

- Opening of the shaft and securing of the site if necessary.

- Setting up the manhole tripod above the center of the shaft. The tripod should be approximately horizontal so that the laser scanner can be lowered into the center of the shaft.

- Mounting the scanner to the manhole tripod using the overhead adapter.

-

Turning on the scanner and activating the wireless remote connection.

Creating a project and setting the corresponding parameters in the scanner. - To start with the lowest scan in the shaft, the scanner is lowered section by section. This is done either with the hand crank or in a faster way with a cordless screwdriver. Gradually, the rod segments of the manhole tripod are added to achieve the necessary depth in the shaft. Then the scanning process is started with the help of a smartphone via the remote connection. Once the scan has been completed, a preview can be viewed.

- Further scans now follow along the entire height of the shaft: approximately every 1m – 2m a scan. Depending on the further processing of the scan data, however, this distance can be flexibly selected.

- The topmost scan is performed about 0.5m above the surface. In this scan, the reference spheres (at least 3 spheres) are also placed well distributed around the shaft opening so that they are visible to the laser scanner. After the last scan has been performed, the scanner can be switched off and disassembled. The manhole tripod can be removed and the shaft closed again.

- For georeferencing, the sphere positions must now be measured, e.g. with a GNSS receiver. Alternatively, this can also be done by total station, provided that known connection points of sufficient quality can be found in the surrounding area.

The survey is now complete. An experienced operator needs max. 1 hour for this.

Workflow of the analysis

- Backing up the scan data and the GNSS points

- Merging of the individual scans with each other. This is done automatically in the FARO SCENE software using Cloud-2-Cloud registration. The result after successful merging is an overall 3D point cloud, i.e. a digital image of the surveyed shaft.

- Georeferencing is also performed in the FARO SCENE software. First, the centers of the reference spheres placed in the last (top) scan are determined. This is done automatically using the search algorithm in the FARO SCENE software. When importing the GNSS points, make sure that the height offset between the sphere center and the ground point determined with the GNSS receiver has been taken into account beforehand. Then a 3D transformation is performed, aligning the scan data to those with GNSS reference points.

- The processing of the scan data including georeferencing is now complete. An experienced operator needs max. ½ hour for this process.

- The overall point cloud can now be exported and further processed e.g. in PointCab software or a CAD software.

Survey of a sewage manhole by means of laser scanner (1) and GNSS (2)

Survey of a sewage manhole by means of laser scanner (1) and GNSS (2)

Do you have questions about how to best execute your projects? Simply send us a mail to info@laserscanning-europe.com or call us at +49 (0)391 6269960.

> Laser scanner accessories for your projects