3D Laser Scanning in Shipbuilding

TitleEfficient capture of free-form surfaces & complex structures

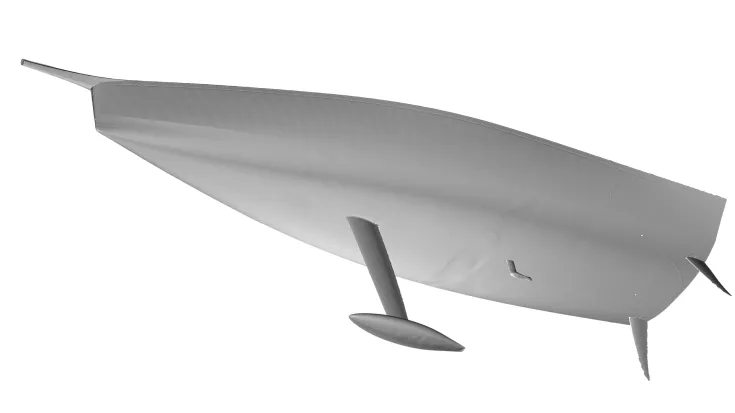

Laser scanning is a modern and precise process that has a wide range of applications in shipbuilding. From capturing the free-form surfaces of a ship's hull to complex installations and superstructures such as engine and piping technology – laser scanning can be used to capture even the most complex structures in detail and with precision.

3D laser scanning is revolutionizing shipbuilding by creating high-precision digital images of ship hulls, engine rooms, pipelines and other structural elements. Shipyards, shipping companies and engineering firms benefit from this technology to carry out new constructions, modernizations and maintenance work more efficiently and cost-effectively.

TitleAdvantages of 3D laser scanning for shipbuilding

High accuracy

Laser scanning captures data accurate to the millimeter, making it possible to precisely map complex geometric shapes. This accuracy minimizes the risk of errors during the construction and renovation process.

Fast capture

Rapid, non-contact surveying with laser scanners significantly reduces the time required on site. This means shorter project lead times and faster implementation of new buildings or maintenance work.

Cost efficiency

By reducing rework and planning errors, 3D laser scanning lowers the overall cost of a project. Fewer working hours and material losses also help to reduce costs.

Digital twins

The captured data is converted into digital models that can be used for further planning and simulations. These digital twins enable a precise analysis of the ship's structure and support optimization decisions.

Easy integration into CAD systems

The point clouds and 3D models created can be easily integrated into standard CAD software, making the transition from surveying to planning and construction seamless.

Flexibility for conversions

3D laser scanning makes it possible to efficiently measure existing ships and use the results for conversions or adaptations. This allows customized solutions to be developed that meet the specific requirements of a project.

Improved quality assurance

By accurately documenting the as-built condition, deviations during the construction or renovation process can be quickly identified and rectified, resulting in a higher quality end product.

Safety improvements

The use of 3D laser scanning reduces the risk of accidents and injuries, as measurements can often be taken from a safe distance. In addition, the precise capture of structures enables potential hazards to be identified at an early stage and appropriate safety measures to be planned.

By using 3D laser scanning in shipbuilding, companies can

- optimize their work processes,

- reduce costs and

- and increase the quality of their products.

This advanced technology therefore represents a significant step towards more efficient and precise ship design.

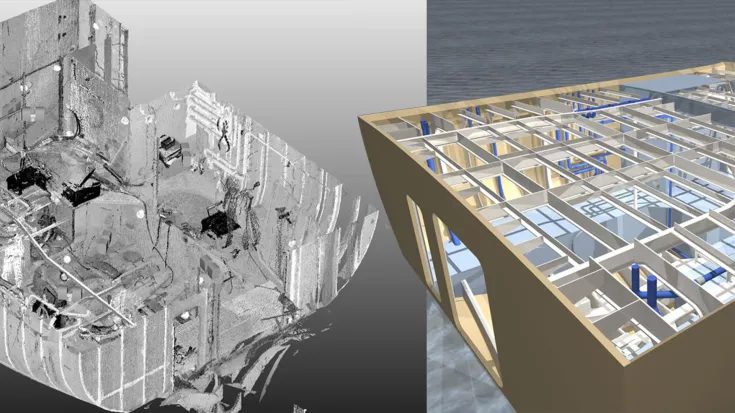

TitleFrom scan to 3D model

For many applications, it is sufficient to create sections through the hull. These 2D sections can be easily imported into standard CAD systems for further processing. For more complex conversion and construction projects, however, it makes sense to create a detailed 3D CAD model. This offers the following advantages:

- Efficient planning process: A 3D model that is accurate in terms of deformation enables the engineering team to optimize the planning process and identify adjustments at an early stage.

- Up-to-date as-built documentation: Modern ship designs benefit from accurate as-built documentation created on the basis of up-to-date 3D data.

TitleReverse engineering & target/actual comparisons in shipbuilding

Special reverse engineering software packages are essential to ensure the precise capture of free-form surfaces and the creation of 3D models in shipbuilding. These software solutions offer extensive functions for converting the captured point clouds into NURBS surfaces, which are particularly suitable for complex geometries thanks to their flexibility and accuracy.

In addition, extensive analysis tools can be used to carry out target/actual comparisons. These comparisons are crucial to ensure that new components fit perfectly into existing structures, guaranteeing accuracy of fit and quality in production. By integrating these modern technologies into the workflow, companies can not only increase efficiency, but also shorten development time and reduce overall costs.

TitleAreas of application for 3D laser scanning in shipbuilding

Design & construction

In the design phase, laser scanning enables the precise capture of the existing geometry of ship hulls and other structures. Engineers can create accurate digital models that serve as the basis for designing new components.

As-built survey

When renovating or repairing ships, an accurate as-built survey of existing structures is essential. Laser scanners provide detailed point clouds that enable complete documentation of current conditions.

Collision checks

The digitalization of ships and their components makes it possible to detect potential collisions or fitting accuracy problems at an early stage. Designers can use target/actual comparisons to ensure that new parts can be integrated into existing structures without any problems.

Quality assurance

Laser scanning plays a central role in quality assurance. By continuously monitoring the components, deviations can be identified and rectified immediately, which improves the quality of the end product.

Reverse Engineering

If existing components are to be rebuilt or optimized, laser scanning enables an exact reproduction of the geometry. This is particularly important for older ships where original plans may no longer be available.

Assembly planning

By creating precise 3D models, assembly can be planned efficiently. This not only reduces construction time, but also minimizes the risk of errors during installation.

Ship inspections

Laser scanning can be used to carry out inspections in areas that are difficult to access. This improves the safety and efficiency of inspections, as all relevant data can be captured remotely without workers having to enter dangerous areas.

Documentation & archiving

The digital capture of vessels and their components enables comprehensive documentation, which is important for future reference and maintenance work. This data can be stored in digital archives to ensure a complete history of the ship's structure and changes.