Laser scanning allows accurate replacement of column

Durch die dreidimensionale Vermessung einer Kolonne wurde sichergestellt, dass ein Nachbau zur Originalkolonne identisch ist. Das Ziel des Anlagenbauers war es, eine veraltete Kolonne in einer bedeutenden Raffinerie in Hamburg durch eine neue zu ersetzen.

TitleUnzuverlässige alte Zeichnungen der Kolonne

Von der Kolonne standen lediglich bis zu 35 Jahre alte Fertigungszeichnungen zur Verfügung, auf denen das Objekt nur in 2D Ansichten bzw. Schnitten abgebildet war. Da solche Fertigungszeichnungen im Rahmen der Anlageninstandhaltung und Anlagenwartung nur selten gepflegt und aktualisiert werden, waren sie für dieses Projekt nicht zuverlässig genug.

Die Vergangenheit hat gezeigt, dass ca. 90% der Equipments beim Einbau nicht passgerecht sind, wenn sie auf Grundlage von veralteten Fertigungszeichnungen rekonstruiert wurden. Aus diesem Grund ist eine reale Planungsgrundlage für den professionellen und somit zeitsparenden Austausch einer Kolonne erforderlich. Laserscanning stellt durch die präzise, digitale Abbildung und die hochgenauen 3D-Daten eine äußerst effiziente Lösung dar.

Title3D Laserscanning ersetzt das klassische Aufmaß einer Kolonne

Für das klassische Aufmaß sind Sichtbehinderungen von Nachteil. Zudem sind aufgrund der Komplexität der Kolonne und deren Anbauten die Vermessung und später auch die Interpretation der aufgemessenen Einzelpunkte erheblich komplizierter und zeitaufwendiger. Zusätzlich entstehen beim Aufmaß von Hand erhebliche Kosten für das einrüsten der Kolonne.

Besonders aus sicherheitstechnischen Aspekten ist das berührungslose Messverfahren des Laserscanners für die Vermessung schwer zugänglicher Bereiche prädestiniert. Das klassische Aufmaß, also die Einmessung mittels Tachymetrie oder mittels Disto und Maßband, liefert dem Konstrukteur Einzelpunkte. Die Konstruktion des CAD-Modells erfolgt dann über diese Einzelpunkte bzw. über vor Ort erstellten und eingemessenen Hilfskonstruktionen.

Die Herausforderung besteht in der richtigen Interpretation der gewonnenen Messpunkte durch den Konstrukteur bzw. durch den Planer. Dieses gestaltet sich immer dann schwierig, wenn der Konstrukteur nicht vor Ort war bzw. nicht ausreichend Maße gemessen wurden.

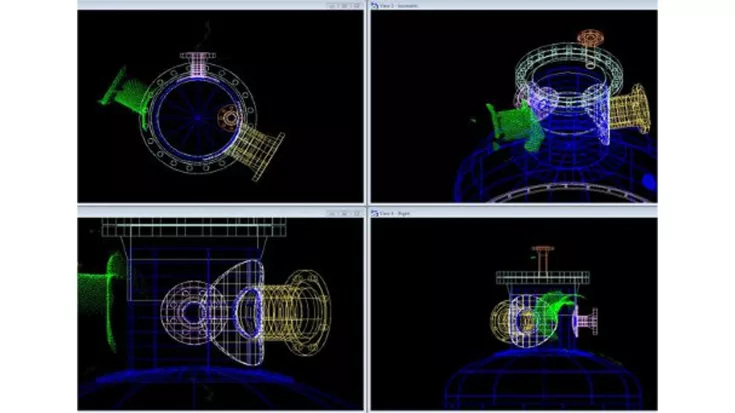

Das Laserscanning erstellt dagegen ein vollständiges Abbild der kompletten Kolonne und ermöglicht es dem Planer, jederzeit die gewünschten und erforderlichen Informationen aus den Laserscanner-Daten abzuleiten.

TitleLaserscanning revolutioniert Konstruktionsplanung

Laserscanning Europe GmbH stellte für das Projekt seine Fachkompetenz zur Verfügung und übernahm die Vermessung und Datenauswertung. An nur einem Tag erstellte das Unternehmen mit einem 3D-Laserscanner 22 Scans von der Anlage und hatte anschließend ein exaktes, maßstabsgerechtes Abbild des Objekts vorliegen.

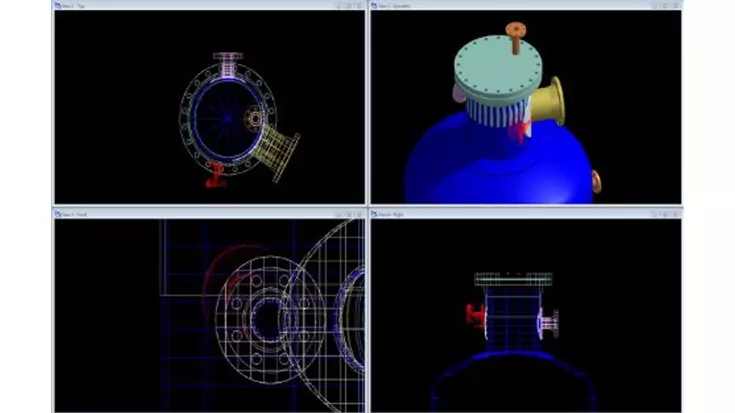

Die Modellierung der Kolonne entsprechend der Fertigungszeichnungen wurde in Microstation umgesetzt und hat ebenfalls nur wenige Tage in Anspruch genommen. Ein weiterer Tag wurde für den Datenabgleich, die Kontrolle und die Erstellung der Dokumentation benötigt. Mit dem klassischen Aufmaß wäre ein Projekt dieser Komplexität nicht in der Kürze der Zeit möglich gewesen.