Survey of a cavity with the GeoSLAM ZEB Horizon

TitlePräzision in der Tiefe: 3D-Hohlraumvermessung im Bergwerk Hattorf/Wintershall

Im Bergwerksbetrieb Hattorf/Wintershall der K+S Minerals and Agriculture GmbH wurde ein anspruchsvolles Vermessungsprojekt durchgeführt: die dreidimensionale Erfassung eines 70 Meter tiefen Bunkerhohlraums, rund 500 Meter unter der Erdoberfläche. Ziel war es, das aktuelle Speichervolumen und den Zustand der Förderanlage zu bestimmen — trotz erschwerter Bedingungen wie Staub, Materialanhaftungen und eingeschränkter Zugänglichkeit.

Zum Einsatz kam der mobile Laserscanner GeoSLAM ZEB Horizon, der mit einem speziell angepassten Cradle durch einen engen Schacht abgeseilt wurde. Unterstützt durch geschulte Mitarbeiter der Grubenwehr wurde nicht nur höchste Präzision sichergestellt, sondern auch der Sicherheitsstandard gewahrt. Erfahren Sie, wie modernste Messtechnik und präzise Planung es ermöglichten, diesen unterirdischen Raum effizient und sicher zu vermessen.

Site of measurement

The object of measurement is located in the Hattorf/Wintershall mining facility of the company K+S Minerals and Agriculture GmbH. This is a cavity (underground, vertical conveyor system) about 500m below the earth's surface with a depth of 70m.

Problem & task

The cavity probably no longer has the original storage volume due to material deposits from years of operation. The environment is dusty and it is expected that material will be deposited within the conveyor system at any time. The cavity is not accessible to humans from any opening. Access is only possible through the 1m diameter openings.

The objective is to obtain the three-dimensional survey of the conveyor system with highest possible resolution for inspection of the system condition; it serves as a data basis for the system operator. Furthermore, strict compliance with all work safety regulations, with minimal risk for the measuring team, is required.

Equipment

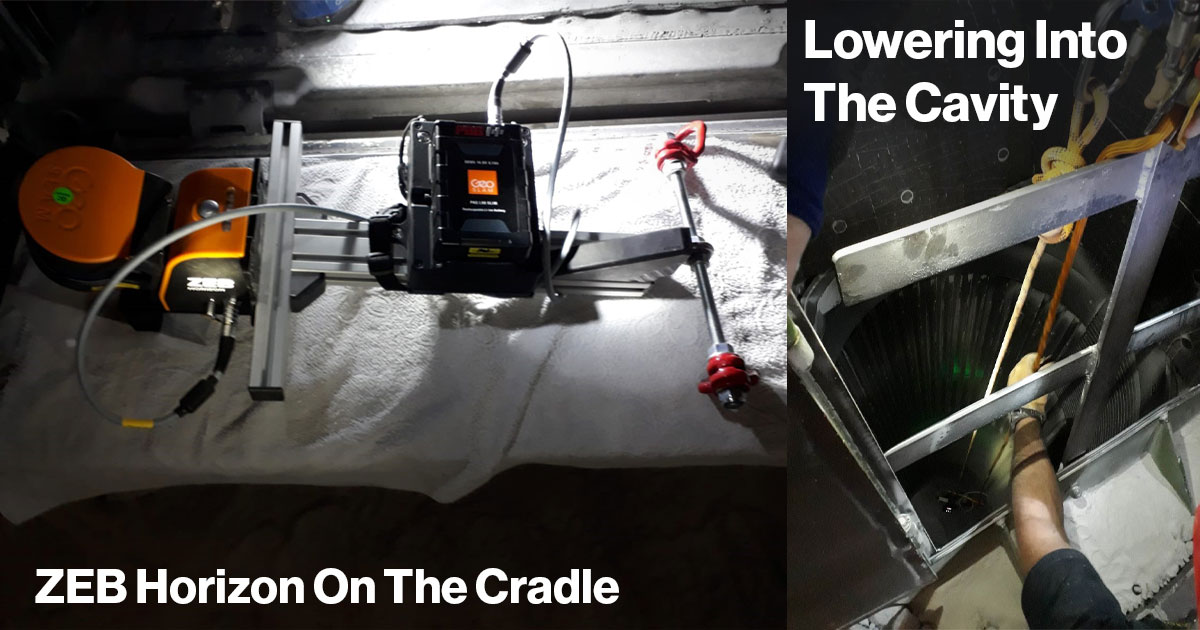

For this job, a mobile laser scanner was used. Thanks to its specifications, the GeoSLAM ZEB Horizon is ideally suited for the special conditions underground. The scanner is also suitable for surveying a cavity that is only accessible from above through a narrow shaft.

The scanner was mounted on a special cradle. The cradle was modified to minimize rotational movements when lowered. A 50m rope was attached to the cradle, which was used to lower the measurement system into the cavity.

In addition, trained members of the mine rescue team were on site to provide security and enable the scanner to be lowered and retrieved safely.

Measurement procedure

- Entering the mine with the equipment

- Preparation of the survey: mounting of the scanner on the cradle and mounting of the rope system for lowering and raising the scanner

- Starting the measurement at the upper end of the opening to the cavity

- Lowering of the scanner, 50m deep. The measurement is running.

- Raising the scanner, 50m high. The measurement is running.

- Finishing the scanning process at the upper end of the opening to the cavity.

- Ascent from the mine and analysis of the scan data in the office.

Workflow of the analysis

Following the survey, the scan data was processed using the GeoSLAM HUB software. The processing of the raw data, i.e. the processing of the point cloud from the data of the laser sensor and the IMU, is automated as far as possible. In the case that a scan is not processed automatically (e.g. because few geometric changes are found in the object space), the focus of the SLAM algorithm can be influenced by adjusting various parameters. After successful processing, a completed point cloud of the cavity is now available in *.laz format. All other common point cloud formats can also be exported with little effort.

Since the scanner could only be lowered linearly on the rope, the earth deposits shadow smaller areas inside the cavity.

Results

The result of this scanning is impressive. This cavity, which is not accessible to humans, was successfully surveyed with the help of the GeoSLAM ZEB Horizon. The point cloud documents the dimensions of the cavity according to the requirements. Further missions with the GeoSLAM ZEB Horizon with similar objectives are already being planned and implemented.

Conclusion

Following this successful test, the company K+S Minerals and Agriculture GmbH decided to purchase one of our mobile scanning systems. We then went to a mine with K+S Minerals & Agriculture GmbH and the GeoSLAM ZEB-Horizon mobile 3D laser scanner. On site we trained the employees of K+S in the correct use of the 3D scanner and then reviewed the 3D data in the office:

Call us now!

+49 391 62 69 960 | +49 7153 66 29 112 | +49 2151 60 32 955

Better aks by mail?

TitleAblauf der Messung

- Einfahrt ins Bergwerk mit dem Equipment

- Vorbereitung der Hohlraum-Vermessung: Montage des Scanners auf dem Cradle und Montage des Seilsystems zum Herablassen und Hinaufziehen des Scanners

- Starten der Messung am oberen Ende der Öffnung zum Bunkerhohlraum

- Herablassen des Scanners, 50 m tief. Dabei läuft die Messung

- Heraufziehen des Scanners, 50 m hoch. Dabei läuft die Messung

- Beenden des Scanvorgangs am oberen Ende der Öffnung zum Bunkerhohlraum

- Auffahrt aus dem Bergwerk und Auswertung der Scandaten im Büro

TitleAblauf der Auswertung

Die Scandaten wurden im Anschluss an die Vermessung mit der Software GeoSLAM HUB prozessiert. Die Prozessierung der Rohdaten, das heißt die Berechnung der Punktwolke aus den Daten des Lasersensors und der IMU, erfolgt weitestgehend automatisiert. Für den Fall, dass ein Scan nicht automatisch prozessiert wird (z. B. weil wenige geometrische Veränderungen im Objektraum zu finden sind), können die Schwerpunkte des SLAM-Algorithmus durch die Anpassung verschiedener Parameter beeinflusst werden. Nach erfolgreicher Prozessierung liegt nun eine fertige Punktwolke vom Bunkerhohlraum im *.laz-Format vor. Alle anderen gängigen Punktwolkenformate lassen sich mit geringem Aufwand ebenfalls exportieren.

Da der Scanner nur linear am Seil abgelassen werden konnte, verschatten die Aufschüttungen kleinere Bereiche im Innern des Hohlraums.

TitleErgebnisse

Das Ergebnis dieser Hohlraum-Vermessung ist beachtlich. Dieser für den Menschen nicht zugängliche Hohlraum konnte mit Hilfe des GeoSLAM ZEB Horizon erfolgreich vermessen werden. Die Punktwolke dokumentiert die Ausmaße des Hohlraums entsprechend den Anforderungen. Weitere Einsätze mit dem GeoSLAM ZEB Horizon mit ähnlichen Zielstellungen befinden sich bereits in Planung und Umsetzung.

TitleFazit

Im Anschluss an diesen erfolgreichen Test entschied sich die Firma K+S Minerals and Agriculture GmbH zum Kauf eines unserer mobilen Scanning-Systeme. Wir waren mit der K+S Minerals & Agriculture GmbH und dem mobilen 3D-Laserscanner GeoSLAM ZEB-Horizon anschließend in einem Bergwerk unterwegs. Vor Ort gaben wir den Mitarbeitern von K+S eine Einweisung im korrekten Umgang mit dem 3D-Scanner und betrachten anschließend die 3D-Daten im Büro:

Die Scanner von GeoSlam sind nicht mehr erhältlich. Wir bieten Technik der neuen Generation an. Fragen Sie uns, falls Sie Fragen haben.