Volume determination for inventory purposes by means of laser scanning

TitleEffiziente Volumenmessung – Wie der GeoSLAM ZEB-Horizon Inventurprozesse revolutioniert

Mit dem mobilen Scanner GeoSLAM ZEB-Horizon sind schnelle Aufnahmen von Punktwolken in vielerlei Hinsicht möglich. Ob für den Indoor- oder Outdoor-Einsatz ist dabei frei wählbar.

Im Rahmen eines Projekts konnten wir durch den Einsatz des Scanners bei Inventurarbeiten helfen, diese signifikant zu beschleunigen und präzisieren. Es handelte sich dabei um Mineralstoffe, welche in- und outdoor in Gruben, Lagerboxen und Lagerhallen deponiert wurden. Nach Angaben des Auftraggebers wurde die Volumenbestimmung in der Vergangenheit sehr aufwändig betrieben. Händisch wurde ein grobes Punktraster auf den Oberflächen der Ressourcen gemessen. Dieser Prozess dauerte bei der Anzahl der Haufen etwa zwei Wochen; mit Hilfe des ZEB-Horizon wurde der Zeitaufwand auf einen Tag reduziert. Darüber hinaus ist auch das Punktraster letztendlich deutlich dichter, sodass die Ergebnisse präzisiert werden.

Using the mobile scanner GeoSLAM ZEB-Horizon, fast imaging of point clouds can be achieved in many ways. It doesn't matter whether it's for indoor or outdoor use.

Within the scope of a project, we were able to help to significantly speed up and precise inventory work by using the scanner. The materials in question were minerals that were deposited in pits, storage boxes and storage halls, both indoors and outdoors. According to the customer, the volume determination was very complex in the past. A rough dot matrix was measured manually on the surfaces of the mineral resources. This process took about two weeks with the number of piles; with the help of the ZEB-Horizon the time required was reduced to one day. In addition, the points are also finally much more dense, so that the results are more precise.

Capture by laser scanning

The GeoSLAM ZEB-Horizon is a mobile laser scanner with a range up to 100m. Due to the SLAM algorithm that is used, no reference points or the like are needed during local scanning. The device is easy to use and requires only one backpack with all accessories. After switching on and starting the measurement, the operator guides the scanner in his hand and measures the object while walking.

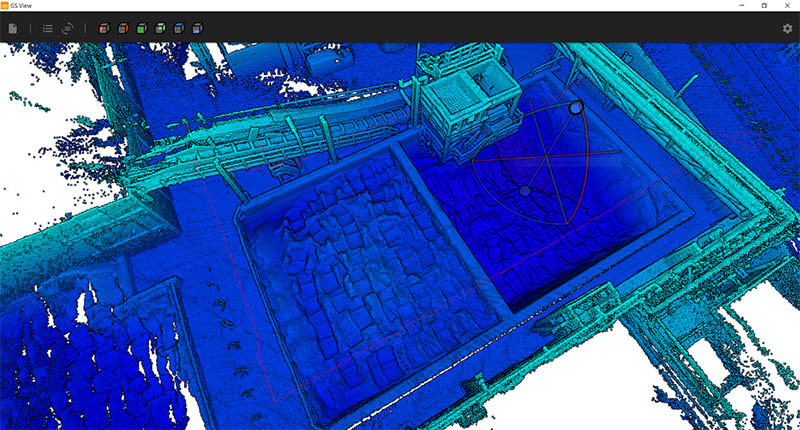

For the volume determination of mounds, we were able to generate a dense point cloud in a very short time by simply walking around a mound. However, the raw materials are not always freely accessible, but are also located in storage halls or storage boxes. The ZEB-Horizon was also successfully used for this case. With the help of a crane, which could move over the raw materials, complete scans of the storage boxes were taken.

Processing of the scan data

We imported the captured data into the GeoSLAM Hub software. The SLAM algorithm was re-calculated and refined, so that we obtained a precise point cloud as the final result. For measurements with several scans, the single point clouds were merged in the software via a cloud-to-cloud registration.

For the analysis, *.LAZ files were passed and imported into PointCab software.

Analysis

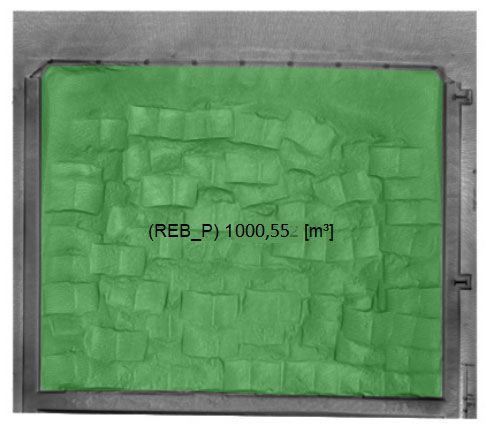

The analysis was performed in the point cloud software PointCab. PointCab offers a reliable platform for processing point clouds; even large-volume point clouds can be processed in the application.

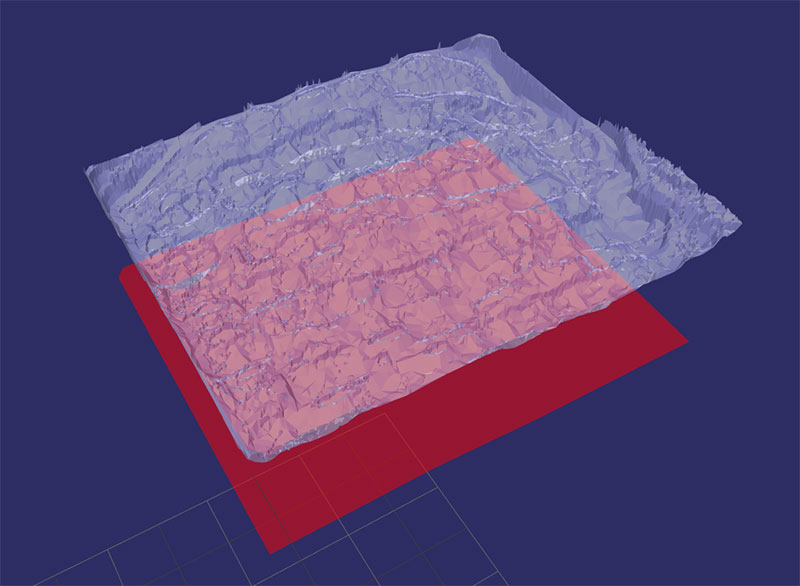

Depending on local conditions, the point cloud first had to be prepared for volume calculation. The point cloud had to be levelled and aligned, which makes it easier to refer the volume to a plane (e.g. ground). The volume is usually determined in the top view of the point cloud, so that no objects (e.g. roofs) lie above the raw materials in the exported point clouds. After preparing the point clouds, the volume calculation tool of PointCab can be used to limit the area in which the raw materials are located. The volume of the surface of the raw material is calculated up to a reference plane. If the reference plane is not visible for pits, a height offset of a known height must be calculated (e.g. upper edge of wall).

If below the raw materials there are invisible, irregular structures which could result in a different volume, a volume difference is calculated on the basis of construction drawings and deducted from the total volume. The volume is calculated perpendicularly from the surface of the raw materials to the reference plane, so that pits that narrow downwards must be corrected using the volume difference.

Conclusion

The capturing of the resources with the help of the GeoSLAM ZEB-Horizon saves an enormous amount of time for the company. In addition, we achieve a high coverage of the surface due to the dense point cloud, which gives a more precise result than with manual measurement methods. As a service provider, we have received very good feedback on the results of this project, so there is nothing standing in the way of further cooperation.