3D Scanning in the Water & Wastewater Sector - Precise Surveying & Digital Planning

TitleDigital documentation: Efficient planning for water & wastewater

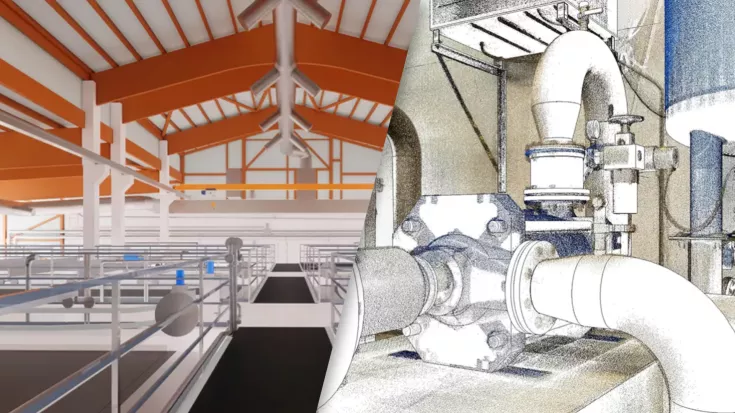

Whether it's an underground sewer network, an extensive wastewater treatment plant, or a complex pipeline infrastructure, water and wastewater management relies on reliable data. With modern 3D laser scanners, UAVs, GNSS, and photogrammetric methods, existing structures can be captured with millimeter precision, digitally modeled, and efficiently analyzed. The result: better planning, greater safety, lower costs – from maintenance to renovation. We show you how modern measurement technology can advance your projects.

TitleAreas of application

Laser scanning has a wide range of applications. Sewer networks can be inspected and documented in detail, enabling damage to be detected at an early stage. In sewage treatment plants, high-resolution scans support the planning of conversions and extensions. Hydraulic structures such as dams, pumping stations, and flood protection systems benefit from the accurate mapping of the structure's geometry. Pipes and tubes can also be efficiently digitized, ensuring optimized maintenance. Renovation and modernization measures can be planned and implemented in a targeted manner based on the data obtained.

Other typical applications include collision and feasibility checks, the preparation of tenders, and support for construction and assembly work. In addition, the digital as-built data is used for maintenance planning, technical documentation, and employee training. Especially in the case of complex systems, 3D scanning increases planning reliability and reduces costly surprises during implementation.

TitleTechnologies & methods

Laser scanning in the water and wastewater industry is based on various technologies that are combined depending on the area of application. LiDAR scanning and photogrammetry enable high-precision capture of structures and terrain. Mobile and terrestrial scanning systems offer flexible options for data collection, whether for large-scale facilities or areas that are difficult to access.

The use of UAVs enables efficient aerial surveying, while integration with GIS and BIM systems ensures seamless further processing and analysis of the captured data.

Combination with other technologies

3D scanning becomes particularly powerful when combined with complementary technologies. Drones capture outdoor areas, roofs, and hard-to-reach structures, while sonar surveys cover underwater areas such as basins or channels. In conjunction with Digital Twin platforms and 3D viewers, holistic, interdisciplinary data models are created that provide a complete overview of the entire infrastructure – from the surface to underwater.

TitleWhy use 3D scanning in water and wastewater management?

Water and wastewater infrastructure is often hidden – and that is precisely where the challenge arises. With 3D scanning technology, complex systems and underground networks can be accurately captured – without the need for costly digging work or operational interruptions. The resulting point clouds and 3D models enable comprehensive analysis, forward planning, and a perfect data basis for renovation and maintenance measures. This leads to significant cost savings, as unforeseen problems are identified at an early stage.

At the same time, inspection times are reduced, resulting in fewer operational failures and higher plant availability. Optimized maintenance planning minimizes long-term risks and increases operational safety. In addition, contactless measurement ensures greater occupational safety, especially in areas that are difficult to access or dangerous.

Operators, planners, and construction companies thus obtain an up-to-date picture of reality that reduces risks, avoids planning errors, and significantly improves collaboration across all project phases.

TitleAdvantages at a glanvve

- Accurate data collection: Millimeter-precise surveying of shafts, pipes, basins, and buildings

- Fast assessment: Significantly reduced time and personnel costs compared to manual methods

- No downtime: Scans can be performed during ongoing operations

- Maximum safety: Measurement possible without direct access to hazardous areas

- Digital Twins: 3D models usable for BIM, GIS, and CAD

- Documentation & tracking: Condition, location, and changes can be tracked at any time

TitleScan-to-Digital-Twin approach

With the Scan-to-BIM or Scan-to-Digital Twin approach, the captured point clouds are systematically converted into structured 3D models. These so-called as-built models represent the actual condition of the plant and can be seamlessly integrated into existing BIM, CAD, or GIS environments. This creates a Digital Twin of the plant, which is used not only for planning and conversion, but also for operation, maintenance, and long-term documentation – as a central, up-to-date data source for all parties involved.

TitlePractical examples & reference projects

Successful scanning projects in the water industry demonstrate the benefits of this technology in practice. One of our user reports, for example, documents the increase in efficiency through 3D measurement.

We are sorry, but the following reports are only available in german language. However, they provide a good insight into the scanning and modelling work.

Bestandsmodellierung eines Bereiches der Kläranlage Bremen-Seehausen

Bestandsmodellierung von Regenbecken und Regenüberläufen

3D-Modell Regenüberlaufbecken, Rechenhalle, Sandfanggebäude und Dükerhalle

Bestandsmodellierung eines Pumpenraums im Wasserwerk Überlingen am Bodensee

Take a look at our video to see how a precise CAD model is created from a point cloud – from data acquisition to modelling.

Our company, Laserscanning Europe, supports you throughout the entire process chain: from data acquisition and scanning to measurement and the creation of 3D models and digital twins. Contact us for a personalised consultation!