Digital Twin in Industrial Applications

TitleDigital Twin – a practical approach

The Digital Twin makes industrial facilities transparent, manageable and efficient. Instead of relying on outdated plans or assumptions, you get a precise digital copy of your real facility – including geometry, conditions and relevant process data.

Whether for factory planning, modifications during operation, maintenance or simulation: an industrial Digital Twin combines 3D laser scanning, modern software and real-time information to form a central basis for decision-making. The result? Fewer downtimes, better planning and maximum control over complex plants.

TitleIndustry 4.0

Digital Twins have long been more than just a digital replica or a once-created 3D model. In daily work with existing facilities, brownfields and complex infrastructures, it quickly becomes apparent that the real added value only arises when geometry, assets and information are brought together in a consistent context.

In practice, teams work with point clouds, CAD and BIM models, technical documents, asset data and operational information – often spread across different systems. Models become outdated, data loses its connection to reality and decisions are made on the basis of incomplete information.

A Digital Twin is not just a 3D image, but a living digital representation of a production environment that serves as a decision-making aid.

While BIM is mainly used in the planning and construction phase, the Digital Twin accompanies the entire life cycle of an industrial plant – from surveying and operation to conversions, maintenance and optimisation.

benaco is a central software for the implementation and visualization of Digital Twins. It creates the basis for robust Digital Twins by combining current geodata, 3D models and operational information into a consistent, realistic digital image. The following video introduces benaco's basic functions and shows how key features support the visualization and editing of Digital Twins.

What is a Digital Twin?

A Digital Twin is a virtual copy of a real-world object, system or process that combines 3D modelling, sensor data and operational information to digitally represent the state and performance of the physical world. Such Digital Twins enable performance monitoring, analysis, simulation and improved operational decision-making.

A usable Digital Twin combines:

- Geometry from point clouds/meshes, CAD or BIM

- Assets and object structures with clear assignment

- Information, documents and operating data located directly on the object

It is not only the pure representation that is crucial, but also the connection of space, object and data, so that a Digital Twin serves as a central, reliable database (single source of truth).

Integration of CAD, BIM & IoT data

An industrial Digital Twin unleashes its full added value by bringing together a wide variety of data sources. CAD and BIM models provide structured geometry and object information, while IoT and sensor data reflect the current status of machines, systems and processes. The intelligent integration of this data creates Digital Twins that not only show how a system is structured, but also how it is currently operating. Temperatures, running times, flow rates and statuses can be visualised and analysed directly in the 3D model – providing a sound basis for maintenance, simulation and data-driven decisions.

Scan-to-Digital-Twin Workflow

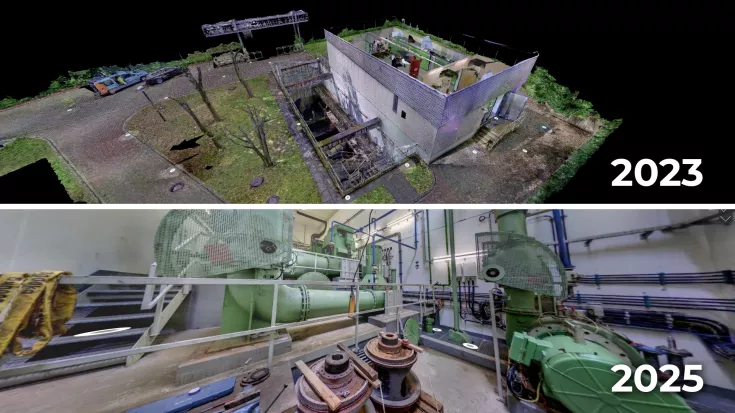

The Scan-to-Digital-Twin workflow begins with a precise documentation using 3D laser scanning. The real industrial plant is captured with millimetre precision as a point cloud – quickly, contactlessly and even during ongoing operations. These point clouds serve as a reliable basis for the creation of as-built 3D models and Digital Twins. Existing CAD, BIM or facility data is then integrated and, if necessary, linked to operational and IoT information. The result is an up-to-date, consistent digital representation of reality that can be expanded, updated and used for a wide variety of applications at any time.

TitleWhy a Digital Twin is so important in industry

A Digital Twin enables:

- Better decisions thanks to accurate, up-to-date data

- Facility planning and layout optimisation prior to actual implementation

- Maintenance and repair based on realistic conditions

- Increased safety through visual and data-based analyses

This leads to:

✔ Faster project launches

✔ Fewer unplanned downtimes

✔ Better communication and planning processes

✔ More efficient collaboration

TitleWhat are the components of an industrial Digital Twin?

A Digital Twin is based on the interaction of geometry, asset structure and information, which together digitally map the real condition of a plant.

| Reality capture & geometry | Asset structure & context | Data & information |

|---|---|---|

Accurate representation of reality is the basis for well-founded decisions. |

Structured assets enable direct access to relevant information. |

Combined with geometry, this creates a single source of truth for planning, operation and maintenance. |

TitleUse and benefits of 3D viewers – maximum transparency for better decisions

Modern 3D viewers make the Digital Twin immediately usable for everyone involved – without CAD knowledge, without local software, directly in the browser. They transform complex 3D data into an intuitive working tool for planning, operation, maintenance and management. Users can virtually walk through facilities, measure distances, check components, set markers or share comments – across locations and in real time. This reduces coordination effort, speeds up decisions and significantly minimises planning errors.

Depending on the application, viewers such as Autodesk Forge, NavVis IVION, Bentley iTwin Viewer or Hexagon Smart Digital Reality Viewer are used. However, the decisive added value lies not in the viewer alone, but in the consistent use of the Digital Twin as a daily work tool: fewer downtimes, shorter project durations, better communication – and a measurable return on investment.

Platforms such as benaco go one step further: As a central Digital Twin platform, benaco combines high-resolution 3D models, point clouds, documents and operating data in a shared environment. The Digital Twin thus becomes a Single Source of Truth for all project participants – from engineering and maintenance to management. Conversions can be checked virtually in advance, maintenance measures can be planned in a targeted manner and investment decisions can be made with confidence.

TitleThe role of benaco in the Digital Twin context

benaco is more than a 3D viewer – it is a comprehensive platform for operational Digital Twin management.

It links geometry, assets and information in a central system and makes the data usable throughout the entire life cycle of a plant.

With benaco, teams can:

- Contextualise point clouds, CAD and BIM models

- Structure and classify assets

- Access documents, operating and maintenance data directly on the object

- Work collaboratively, regardless of location

This combination creates an operationally usable Digital Twin that makes decisions faster, more secure and more transparent.

The following example shows how this works in practice in the form of a virtual tour of the Zollverein Coal Mine Industrial Complex.

TitleThe benaco workflow – typical for existing projects

How Digital Twin teams work with benaco:

The workflow in benaco is directly tailored to the requirements of teams working with Digital Twins. First, existing data is captured using reality capture or existing CAD and BIM models. This data is imported into benaco and structured there: plants, machines and components are created as assets, classified and linked to documents, operating information and metadata. Once the Digital Twin has been fully created, planning, conversion, maintenance and operation can be based directly on it. Changes can be tracked, information remains up to date at all times, and different departments can access the same data simultaneously. The result is a living Digital Twin that maps the entire life cycle of a plant and makes it usable for all parties involved.

Workflow

| Raw data – Digital replica of the actual plant | benaco platform – Processing & enrichment | Viewer - Use & added value |

|---|---|---|

This data forms the geometric and visual basis of the digital Twin. |

In this step, raw data is contextualised and made usable for information purposes. |

The viewer makes the Digital Twin operationally usable and easily accessible for end users. |

TitleEfficient Digital Twin management throughout the lifecycle

With benaco, the Digital Twin becomes a truly operational tool. Whether it's planning renovations, maintenance, safety and training scenarios, or documentation in the inventory, all information is available centrally and in a structured manner. The platform enables assets and their documents to be viewed in a contextualised overall model, which saves time, reduces errors and facilitates informed decisions. At the same time, the Digital Twin remains up to date and traceable throughout its entire life cycle. This allows plants to be operated more efficiently and conversions to be planned more precisely.

TitleWhy benaco is a compelling choice in the Digital Twin ecosystem

benaco is impressive because it not only displays Digital Twins, but also makes them truly usable. The platform acts as a single source of truth, bringing together geometry, assets and information. The as-built-oriented approach plays a particularly important role in existing buildings, as it ensures that decisions are based on current, realistic data. At the same time, benaco is scalable – from individual projects to large sites – and open to all manufacturers and data. This allows different systems, models and documents to be integrated without any problems. In combination with reality capture data such as point clouds or 3D models, benaco becomes an operational platform that efficiently links planning, operation and maintenance.