Shining 3D FreeScan UE Pro2

TitleCompact performance for the highest demands

The FreeScan UE Pro2 from SHINING 3D is a next-generation wireless handheld 3D scanner for industrial metrology. Designed for maximum flexibility, impressive scanning speed, and the highest precision, it enables professional 3D scanning directly on site – whether in production, quality control, or reverse engineering.

Weighing only around 950 grams, the scanner fits ergonomically in the hand and allows comfortable working even over longer periods of time. This combination of lightness and precision makes it an ideal tool for demanding industrial applications.

TitleWireless scanning offers maximum freedom of movement in everyday industrial use

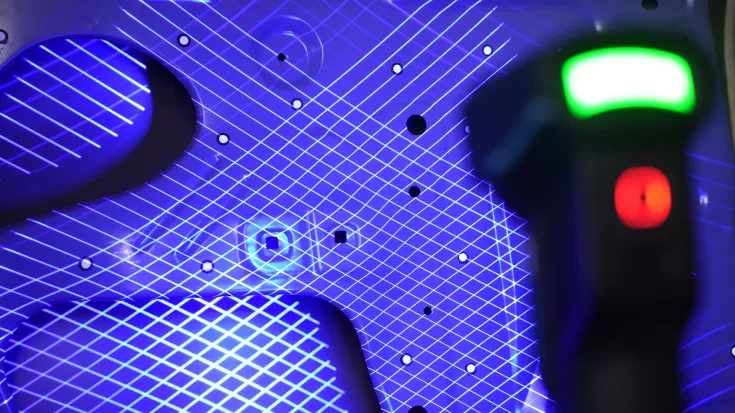

The FreeScan UE Pro2 was developed specifically for wireless use. Thanks to its integrated WLAN module, data is transmitted in real time without any annoying cables. This allows users to work freely in confined production halls, with large components, or outdoors without compromising on precision.

The wireless technology provides greater flexibility and reduces the time required to set up the system. This means that measurements can be started more quickly, significantly increasing efficiency throughout the entire work process.

TitleMaximum efficiency thanks to impressive scanning speed

With a scanning speed of up to 3,460,000 points per second, the FreeScan UE Pro2 is one of the fastest devices in its class. It captures large areas and complex geometries in no time at all without compromising on accuracy.

The high point density ensures detailed and complete data, even on difficult surfaces or highly reflective materials. This makes the scanner suitable for both large-area inspections and precise detail captures of small parts.

TitlePatented photogrammetry for metrological precision

The FreeScan UE Pro2 uses state-of-the-art technology: patented binocular photogrammetry (VPG). This process enables high-precision scanning of large objects without the need for coded markers.

This saves time in preparation and minimizes workflow effort. By combining laser technology and photogrammetry, the scanner achieves volumetric accuracy of up to 0.02 mm + 0.015 mm/m. This has been tested and certified according to ISO 17025 and VDI/VDE 2634. Thus, the FreeScan UE Pro2 not only delivers scans, but also measurable 3D data at the metrology level.

TitleThree scan modes for every requirement

The FreeScan UE Pro2 has three customizable laser scan modes that are optimized for different scenarios.

High-speed mode uses 50 laser lines, making it ideal for large objects and fast measurements. Detail mode with seven parallel laser lines enables precise capture of fine structures and small geometries.

Single-line mode is ideal for particularly narrow areas or hard-to-reach places: with just one laser line, even deep holes, recesses, or edges can be scanned with millimeter precision.

This flexibility allows both macro and micro scans to be performed efficiently with just one device.

TitleCertified precision for industrial quality control

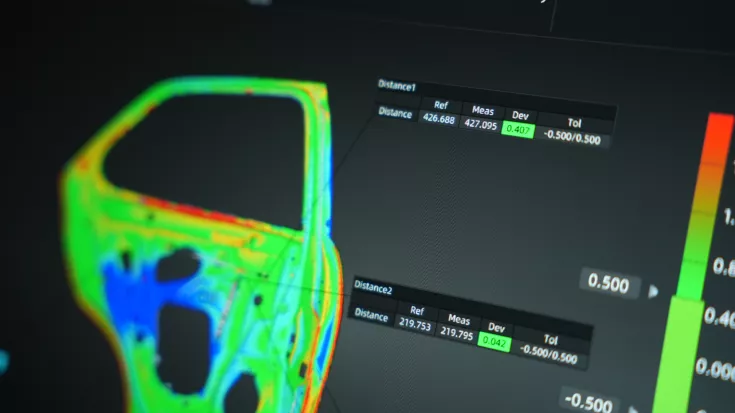

Thanks to its metrological calibration and ISO-certified accuracy, the FreeScan UE Pro2 meets the highest industrial requirements. The captured data can be used directly for quality or target/actual comparisons in common software solutions such as Geomagic Control X, PolyWorks, or GOM Inspect.

Seamless software integration simplifies and accelerates the entire workflow from data acquisition to evaluation.

TitleIntuitive software integration for efficient workflows

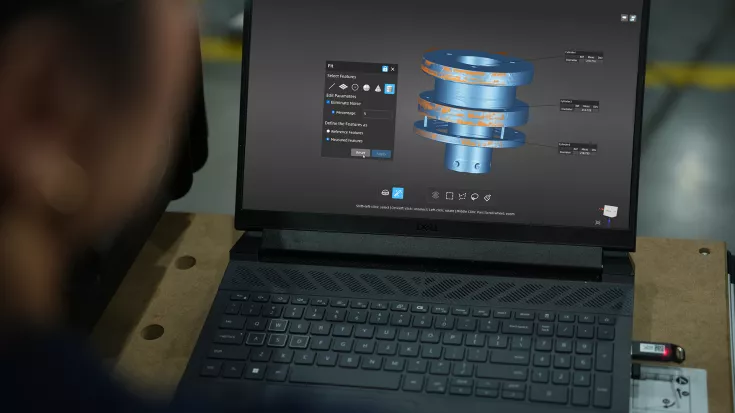

The FreeScan software that comes with the scanner has a clear user interface that provides real-time visualization of the point cloud. Quality indicators, color codes, and automatic prompts guide the user safely through the entire scanning process.

Once the measurement is complete, the data can be exported as a mesh (STL, OBJ, or PLY) and processed directly in CAD or inspection software. This close integration of hardware and software reduces sources of error and increases productivity.

TitleConclusion: Mobility meets precision

With the FreeScan UE Pro2, SHINING 3D sets a new standard for mobile 3D measurement technology. The scanner combines wireless freedom with metrological accuracy, exceptional speed, and intuitive operation.

Whether for quality control, reverse engineering, or production, the FreeScan UE Pro2 offers the perfect balance of performance, precision, and flexibility, making it the optimal choice for professional industrial applications.

TitleAreas of application for the FreeScan UE Pro2

The FreeScan UE Pro2 proves its strengths in numerous industrial sectors: from automotive and mechanical engineering to energy and heavy industry. Thanks to its performance, flexibility and mobility, it is an ideal solution for demanding measurement and inspection tasks.

TitleTypical areas of application

Automotive industry

Automotive manufacturing places high demands on quality, speed, and traceability. With 50 laser lines for capturing flat surfaces and complex details, the FreeScan UE Pro2 is ideal for sheet metal and body parts, surface deformations, or position checks of drill holes.

Mechanical engineering and transportation

Whether machine housings, rail vehicles, or commercial vehicles—the scanner can handle both indoor and outdoor areas, features high-quality material adaptation, and is therefore suitable for reflective or dark surfaces.

Energy, heavy industry, and infrastructure

Large objects such as turbines, pipelines, or large-scale facilities benefit from wireless mobility and photogrammetry mode for high accuracy over large areas.

Other industries

- Aerospace: large structural components, complex shapes

- Research & education: prototyping, high-precision laboratory applications

- Reverse engineering: obsolete components, tool and mold making

- Service and maintenance: mobile on-site inspections

TitleAdvantages in use

- Time savings: Less preparation time thanks to wireless operation and marker-free photogrammetry.

- Mobility: Use directly at the plant or machine without time-consuming transport.

- High quality: Metrology-grade measurement results—not just “scan data,” but usable measurement results.

- Versatility: Handle different object sizes and materials—from small components to large plants.

TitleHow does the FreeScan UE Pro2 work? – Technology & workflow in detail

The performance of the FreeScan UE Pro2 is based on modern measurement technology principles: light sources, photogrammetry, markerless tracking technology, and results integrated directly into the workflow. Below, we explain the underlying technologies and typical work steps.

TitleTechnology highlights

Laser light source modes

Depending on the application, you can choose between three light source modes:

- 50 laser lines (high-speed mode) for fast scanning of large areas.

- 7 parallel laser lines (detail scan) for fine structures and increased resolution.

- 1 laser line (deep hole scan) for scanning in deep holes or narrow pockets.

Photogrammetry (VPG – Video Photogrammetry)

SHINING 3D's patented binocular photogrammetry technology enables spatial positioning without coded markers. This simplifies preparation and increases accuracy for large objects.

Workflow & Software Integration

- The user selects the appropriate scan mode (e.g., mesh scan, detail scan).

- The software (e.g., FreeScan software) displays mesh data in real time, supports templates, and displays data quality (e.g., laser line color, LED indicator).

- Export to common formats (e.g., OBJ, STL, PLY) and transfer to CAD/inspection software (e.g., Geomagic Control X, PolyWorks).

Outdoor and indoor use

Thanks to wireless transmission and robust tracking, the scanner can be used both in the factory and on site in outdoor applications – e.g., for plant inspections or in heavy industry environments.

TitleTypical workflow step by step

1. Prepare the device for use: Connect the battery/power bank and activate the Wi-Fi module if necessary.

2. Object setup: Position the scanner at the appropriate distance; observe the recommended distance depending on the mode.

3. Select the scan mode: e.g., high speed for large areas, detail for fine geometry, deep hole for drill holes.

4. Real-time monitoring: Check mesh data and quality during scanning using software.

5. Data export & processing: Transfer point cloud or mesh to CAD/inspection software, perform measurements, generate report.

6. Result verification: Volumetric accuracy and calibratability enable metrologically usable data.

| Product name | FreeScan UE Pro2 | ||

|---|---|---|---|

| Scan modes | Crossing laser lines | Parallel laser lines | Single laser lines |

| Light source | 50 laser lines | 7 laser lines | 1 aaser line |

| Working distance | 300mm | 200mm | 300mm |

| Scan accuracy | 0.02mm | ||

| Volumetric accuracy | 0.02 + 0.03mm/m (0.02 + 0.015mm/m with photogrammerty) | ||

| Scanning speed | up o 3,460,000 points/s. | ||

| Scanning depth | 360mm | ||

| Maximum field of view (FOV) | 600 x 550mm | ||

| Point spacing | 0.01 ~ 10mm | ||

| Laser class | Class 2 (eye safe) | ||

| Interface | USB 3.0 | ||

| Dimension | 305.8x118.9x100.8mm | ||

| Weight | 0.95kg | ||

| Power supply | 24V, 3.75A | ||

| Operating temperature | -20 ~ 40° | ||

| Working humidity | 10% ~ 90% | ||

| Certification | CE, FCC, ROHS, WEEE, KC, FDA, UKCA, IP50, TELEC, TiSAX | ||

| Accuracy certification | VDI/VDE 2643 Part 3 (certified in an ISO 17025-certified accuracy laboratory) | ||

| Recommended PC configuration | Operating system: Windows 11 Professional 22H2 (64-bit) Processor: 13th Gen Intel Core i7-13700 or better Graphics card: NVIDIA GeForce RTX 4060 (laptop) or better Graphics memory: 8GB or more RAM: 64GB or more, DDR5 dual-channel USB interface USB3.0 | ||

TitleNotes on the specification

- Scan speed: The high number of points per second significantly reduces scanning time for large areas.

- Laser line modes: Three modes enable modular use depending on object size or level of detail.

- Volumetric accuracy: Important in metrology, e.g., for measurement reports or comparison and inspection applications.

- Wireless operation: Flexibility for on-site inspections—reduces setup time and facilitates handling.

- Compatibility: Supports common software and data formats for seamless integration into existing workflows.

Better advice as a user

If you are interested in our offer or would like to learn more about the FreeScan UE Pro2, then call us today and arrange a free and non-binding consultation appointment for you. We will answer all your questions. As a dealer and at the same time a user, we are well positioned to assist you even after the purchase.